Contents

The demand for products containing vitamins and food supplements is growing at a steady pace. An increasing number of people are recognising the importance of taking care of their health, paying attention to the prevention of various diseases, and preventing nutritional deficiencies. This has led to the emergence of new players in the market, with many novice entrepreneurs, experienced businessmen, and large companies planning to create their own brand of nutritional supplements.

However, success in this industry is not guaranteed. Competition is growing, making it challenging for new entrants to gain a foothold. Companies selling vitamins must continually enhance the quality of their service, personalise their offers, and expand their product range. It is important to note that setting up a production facility from scratch is a complex and costly undertaking.

To circumvent these challenges, many entrepreneurs opt for turnkey contract manufacturing of nutritional supplements and vitamins. This is a convenient and expedient method for establishing a brand of products in a relatively short time.

However, selecting the appropriate manufacturing partner is of paramount importance. Firstly, the quality and safety of the finished product depends on it. Secondly, the partner’s experience and production capacity can influence how precisely the future food additive will meet all your requirements and wishes.

Finally, the commercial success and popularity of the product largely depends on the contractor, as he can influence not only the production processes, but also branding, packaging, marketing strategy and other important aspects. For these reasons, the selection of a turnkey partner must be approached with the utmost responsibility.

What is turnkey manufacturing?

Turnkey production of nutritional supplements and vitamins is a complex process of creating a finished product from scratch. In this format of collaboration, the partner can assume responsibility for not only direct production, but also for research, formula development, packaging, obtaining quality certificates and other important processes. As a result, the contract manufacturer creates a fully market-ready product for the customer.

For customers, such turnkey solutions are highly advantageous, as they can obtain a nutritional supplement under their own brand name without having to engage with multiple contractors for different services. It is considerably simpler to oversee processes and save time in creating a supplement from scratch.

It is also important to note that competition in the contract manufacturing industry is rather fierce, which encourages manufacturers to consistently update equipment, introduce innovative technologies, enhance product quality and expand the range of services.

These days, customers can order a partner to produce vitamins, minerals, probiotics, sports nutrition, amino acids and other products that are popular with consumers. The form of the nutritional supplement can also be different — ranging from tablets and capsules to liquids and jelly candies.

Manufacturers have the capacity to create a virtually limitless range of products to meet the most specific needs of their target audience. They can also provide turnkey production of supplements for a wide range of purposes, including immunity, weight loss, endurance, heart health, blood sugar control, and skin and hair.

Why use the turnkey solutions for the production of supplements?

There are a number of reasons why entrepreneurs choose to work with contract manufacturers. Some lack the necessary experience to manage complex technological processes, while others are unwilling to invest in their own production facilities and assume operational risks. Others are constrained by either time or resources.

Let us examine the reasons why customers opt for turnkey solutions for additive manufacturing:

- Necessity and benefits — due to the highly competitive nature of the industry and the requirement to customise solutions to meet the needs of the target audience, it is important for companies to provide high-quality products, bring nutritional supplements to market quickly and adapt to demand trends. Turnkey solutions achieve these goals with the expertise and resources of a partner.

- Savings — turnkey manufacturing offers a significant reduction in costs. Furthermore, the partner can provide a range of value-added services to optimise costs and avoid spreading your budget across multiple contractors.

- Timeframe for creating a finished product — a complete cycle of services in contract manufacturing allows the client to order business strategy development, formula creation, production and other services from a contractor, and in the end receive a fully ready-to-sell product in a relatively short period of time. The manufacturer is able to accurately calculate the time it takes to produce the goods, which is an important aspect, as it allows the client to understand the exact timeframe for each step of production.

- Marketing and sales focus — the utilisation of turnkey solutions enables entrepreneurs to outsource all production processes, thereby allowing them to focus their attention on other crucial tasks such as marketing and sales. This approach facilitates more dynamic brand development and enhanced customer service.

- Quality control — should a client wish to engage in the production of nutritional supplements but lack the requisite education or expertise in this field, they may rely on a partner who adheres to the relevant standards, possesses the necessary certification and can guarantee the high quality and safety of the product.

- Target audience — one of the principal advantages of this production format is its versatility. It is suitable for businesses of different scales and levels of influence, in particular start-ups and enterprises seeking to rapidly expand their product range without significant investment in production capacity.

It is therefore evident that turnkey solutions can be utilised for a multitude of reasons, including the desire to expand a startup or the objective of generating substantial profits through the sale of popular and in-demand nutritional supplements.

It is advisable to discuss all the details with your partner at the outset to ensure that they are able to assist you in meeting the challenges and goals set out. It is important to gather information in advance about product quality, lead times, service costs, product customisation and scalability, and after-sales support.

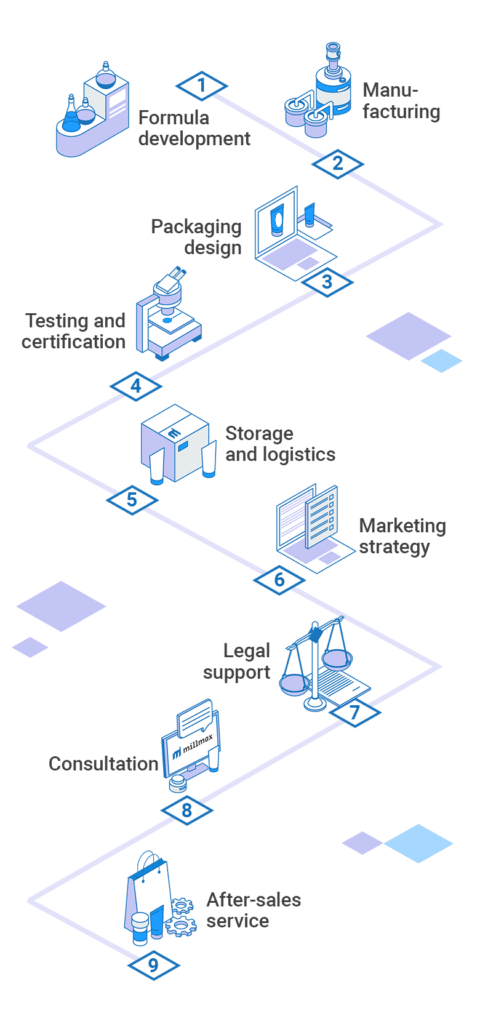

What services can a turnkey value-added manufacturer provide?

It is evident that the primary objective of a contractor is to produce high-quality and safe products. However, turnkey solutions for contract manufacturing of vitamins and nutritional supplements offer a more extensive range of services that are available to be ordered by the customer.

- Formula development. A request can be made to a partner to develop an original, effective and safe formula for a nutritional supplement. Such production facilities employ experienced technologists who will assist in the selection of ingredients, calculation of dosage and testing of the effectiveness of the product. The contractor can also adapt an already ready formula for a new request or create a copy of the finished product.

- Manufacturing. A plethora of manufacturing processes can be employed to produce nutritional supplements and vitamins, including filtration, purification, dehydration, extraction, blending, emulsification, and encapsulation. The specific list and sequence of production steps is contingent upon the type and composition of the product, the ingredients utilised, and the availability of suitable equipment.

- Packaging design. The product’s appearance must comply with the legal requirements of the country where it will be manufactured. The use of turnkey production of additives allows for the engagement of experienced specialists in the development of unique and attractive packaging. In addition to durability, the packaging must also ensure product safety, align with the brand positioning, and differentiate the product from competitors. Various forms of packaging, including bottles, blister packs, zip-lock bags, stickers, and others, can be used for nutritional supplements..

- Testing and certification are crucial stages in the production of a quality and safe product. All incoming raw materials are subjected to rigorous laboratory testing to ensure their suitability for use in the final product. Additionally, test samples of food additives are created and subjected to the same rigorous testing to guarantee that they meet all safety standards. This process also facilitates the acquisition of certificates for quality assurance and marketing authorisation, which are essential for the product’s success in the market.

- Storage and logistics are also vital aspects of the production process. Products such as vitamins and supplements require careful storage conditions to ensure that the goods do not spoil prematurely. A contractor can provide storage facilities where the goods will be stored in accordance with all relevant regulations and standards, including the correct temperature and humidity levels. The partner will also assist with the timely and safe transport of additives. Furthermore, traceability and insurance services will help to mitigate other risks.

- Marketing strategy. You do not necessarily need to look for a separate outsourced contractor to create and implement a marketing strategy — this service can also be ordered from your turnkey partner. The partner will help you create materials for product promotion, choose effective tools and communication channels, and convey brand values to the target audience.

- Legal support. It is possible that there may be discrepancies in legislation and local regulatory requirements across different countries. Consequently, the contractor will provide guidance on the correct procedures for registering a brand, the permits and certificates that should be obtained, and the actions that should be avoided in order to comply with legal regulations.

- Consultation. It is also possible to request the services of a contract manufacturer in order to gain professional advice on a number of different topics. These include product formulation and ingredients, preferred production techniques, increasing the efficiency of different processes, and optimising costs.

- After-sales service. Some contract manufacturers offer customer support even after the product has been manufactured and sold.

Turnkey solutions and what they mean for food manufacturing

The benefits of turnkey solutions for your nutritional supplement business

Turnkey solutions for the nutritional supplements industry offer a number of compelling advantages. Let us examine the most significant of these:

- Time and resource savings. Turnkey solutions obviate the necessity for customers to construct a production facility from the ground up. Instead, they engage a partner that possesses the requisite production capacity, which allows them to save a significant amount of time on product launch and to concentrate their efforts on business development.

- Cost reduction. It is unnecessary to expend capital on the construction or rental of premises, the purchase of expensive equipment, the hiring of a team of qualified employees, the identification of raw material suppliers and the establishment of all production processes. Contract manufacturing enables the avoidance of such significant costs.

- Experience and expertise. By selecting a full-cycle manufacturing facility, it can be reasonably assumed that the manufacturer has accumulated considerable experience and expertise in the production of nutritional supplements and vitamins. Furthermore, such contractors are known to regularly update their equipment, utilise innovative technologies and enhance their service levels, thereby guaranteeing the quality of future products.

- Flexibility and scalability. In general, the production of nutritional supplements in a turnkey manner allows for the consideration of market trends and the ability to adapt to them in a timely manner. This approach enables the adjustment of product needs and the steady development of a brand, including the increase in product volumes, the entry into new markets, the expansion of the product range, the rebranding of the product, and the attraction of new target audiences.

- Quality and safety. It is a requirement of contract manufacturers that they adhere to strict quality standards and that they possess certification which verifies their adherence to good manufacturing practices, quality control and safety standards. This provides the customer with additional assurance that the final product will be effective and will not harm the health of end consumers.

- Value-added services. In addition to the direct production of nutritional supplements and vitamins, a comprehensive range of related services is also available, including formula development, the creation of unique and stylish packaging, the organisation of logistics, and the preparation of a product promotion plan. This allows the customer to exercise full control over their brand without the need to interact with numerous contractors simultaneously.

Potential drawbacks

As with any other business, there can be potential drawbacks to turnkey supplement and vitamin manufacturing. Here are some risks to consider and ways to mitigate them:

Risk №1: Restricted control over the manufacturing process

How to prevent: it is advisable to ascertain in advance whether the contractor possesses the requisite certificates and documents pertaining to quality and safety control. This will assist in determining whether all production processes are conducted in accordance with established rules and regulations. Additionally, it is possible to inquire about the specific technologies that must be employed to manufacture products in accordance with your specific requirements, thereby facilitating a more comprehensive understanding of the production process.

Risk №2: Possible limitations in individual production preferences

How to prevent: it is advisable to consult with experienced technologists in order to ascertain the reasons why certain individual preferences cannot be met during production. If the limitations are due to a violation of generally accepted standards or other objective reasons, it may be possible to adjust the request. However, if the limitations are due to a lack of experience or the absence of necessary equipment, it may be necessary to contact another contractor.

Risk №3: Dependence on service provider schedules and timelines

How to prevent: it is advisable to set realistic production deadlines from the outset. It is important to describe your requirements and wishes as precisely as possible, in order to minimise the number of changes that may be required after the project has been launched. It is also prudent to ascertain the potential penalties that may be incurred if the contractor fails to meet the agreed deadlines, without objective justification.

Risk №4: Too much competition in the nutritional supplement market

How to prevent: it is of the utmost importance to conduct comprehensive market research, gathering data on the target audience and analysing competitors. These findings must be taken into account when developing the concept, naming and brand positioning. A unique selling proposition must be created for the product, and the product packaging must differentiate the product from competitors.

Risk №5: Ecology and sustainable development

How to prevent: it is advisable to request documentation from the contractor confirming the quality of the raw materials used. It is important to ascertain the origin and extraction methods employed. When selecting ingredients, preference should be given to those of plant origin. It would also be beneficial to ascertain whether the partner in question utilises environmentally friendly technologies in their production.

Are turnkey solutions a good fit for you?

Turnkey supplement and vitamin manufacturing represents a potentially advantageous solution for numerous companies and entrepreneurs. However, before reaching a definitive conclusion, it is prudent to consider a number of pivotal factors:

- Business specifics: in the event that a company lacks the requisite production capacity to bring a new product to market, contract manufacturing can be employed as a solution.

- Budget: it is not uncommon for turnkey solutions to appear expensive when initially considered. However, when compared to the costs associated with establishing a production facility from the ground up, the former option is often found to be more cost-effective in the long term.

- Preferred launch time frame: in the context of a compressed timeline for product development, a contract manufacturer can facilitate the completion of all stages of the process in a more expeditious manner.

- Operational risks: turnkey contract manufacturing is a strategy that helps to mitigate many of the risks associated with the manufacturing process, regulatory compliance and quality standards.

- Focus on development: the delegation of product development and manufacturing to outsourcing enables a company to concentrate its resources on the formulation of a successful business strategy, the implementation of marketing activities, the expansion of sales and the further development of the brand.

- Need for innovative solutions: in order to gain a competitive advantage and create a product utilising cutting-edge technologies that are not currently available in-house, it is recommended that a contract manufacturing solution is employed.

- Flexibility and scalability: turnkey manufacturing offers entrepreneurs the flexibility to scale production rapidly, expand their product range, realise new ideas, or rapidly adapt their product portfolio to market trends.

Conclusion

Turnkey production of nutritional supplements and vitamins refers to a set of full-cycle services that enables the customer to receive a fully ready-to-launch product in a relatively short time. This partnership format eliminates the need for large capital investments and the search for different contractors for different tasks.

The customer can outsource most of the processes related to brand concept development, ingredient selection, production process, quality control, packaging development, storage, delivery and the creation of an effective promotion strategy.

One of the most successful contract manufacturers is MillMax, which specialises in health and beauty products, including nutritional supplements and vitamins. This European factory is equipped with all the necessary certificates, state-of-the-art equipment and its own laboratory for product quality control.

Consequently, if one is seeking expedient, turnkey solutions for one’s business at a competitive price point while simultaneously ensuring the quality, efficacy, and commercial viability of the prospective product, MillMax can be relied upon as a dependable partner in the development of a successful brand of vitamins and nutritional supplements.

One thought on “What is a turnkey contract supplement and vitamin manufacturing solution?”

Comments are closed.